Today we celebrate 110 years of operation. Hats off to all Wilson-Hurd employees, past and present, for all of your hard work and dedication. Without you we could never have reached this monumental achievement. Thank you!

Today we celebrate 110 years of operation. Hats off to all Wilson-Hurd employees, past and present, for all of your hard work and dedication. Without you we could never have reached this monumental achievement. Thank you!

Wausau, Wisconsin: Wilson-Hurd Mfg. Co. is pleased to announce the launch of an entirely new branding campaign with the addition of a new company logo. The updated logo represents the first significant branding change for Wilson-Hurd in many years, and is an important step toward many exciting new changes to come.

“In the one-hundred nine year history of Wilson-Hurd, the company’s evolution has been driven by new technologies and demanding customer requirements.” said Jim McIntyre, President of Wilson-Hurd. “Our new logo is a reflection of our integration of new technology and emerging manufacturing best practices into our company while maintaining our traditional high standards of quality and value.” continues McIntyre. “We bring design and manufacturing excellence to our customers through innovation and collaboration. Welcome to the next chapter in the success story of Wilson-Hurd.”

The updated logo brings about a number of significant branding changes for Wilson-Hurd including the following:

About Wilson-Hurd: Wilson-Hurd Manufacturing specializes in the production of custom electronic control products, point-of-purchase displays, plastic and metal nameplates, and contract medical devices. Wilson-Hurd was founded in 1904, and is headquartered in Wausau, WI, with additional locations in Berlin, WI.

Media Contact: Toni Laurich ● Wilson-Hurd Mfg. Co. ● 715-845-9221 ● tonidl@wilsonhurd.com

It’s possible you may have never heard of them, but chances are you have seen ETC’s work. Electronic Theatre Controls, based out of Middleton, WI, currently provides quality products to the following markets; entertainment lighting, specified architectural lighting, and industrial weighing and measuring. You could have seen their products lighting up the stage at the National Theatre in London, or maybe at the Guangzhou Opera House in China, or the 5th Avenue Theatre in Seattle, Washington. Or perhaps you saw their work gracing the outside walls of the new Palazzo hotel in Las Vegas, or climbing the side of the Burj Khalifa in Dubai. ETC has lighted up stages, artwork installations, and architecture all across the globe, and we at Wilson-Hurd have been honored to work with them on a number of projects, including ETC’s own CEM3 system.

The CEM3 system was designed by ETC to help reduce setup time, simplify system backups, and make the process of networking a lighting system run as smoothly as possible. The CEM3 platform provides a simple and risk-free way to control lighting on stages and touring events.

Wilson-Hurd’s engineering team was able to brainstorm and combine the most effective manufacturing capabilities to give the CEM3 system these key features:

“By closely working with Electronic Theatre’s design/engineering team, the Wilson-Hurd team developed a cost effective controller produced in Wisconsin.” says Dan O’Connell, Western Sales Director for Wilson-Hurd. “Our high quality digital press combined with our screen printing expertise produced a high end graphic for this capacitive touch controller.” adds O’Connell. According to Tom Steer, Product Manager at ETC, these product features are what really make a difference backstage, stating “The integrated backlighting (invaluable backstage), numeric keypad and touch wheel have vastly improved the user experience for customers working with our dimming systems, while the cast metal user interface gives the product the robustness it needs to cope with life in the field.” A difference made backstage, can make all the difference onstage.

For more videos from ETC, visit their Youtube channel here.

For more information about Wilson-Hurd’s capabilities, please contact us at 800-950-5013 or visit our website at http://www.wilsonhurdelectronics.com.

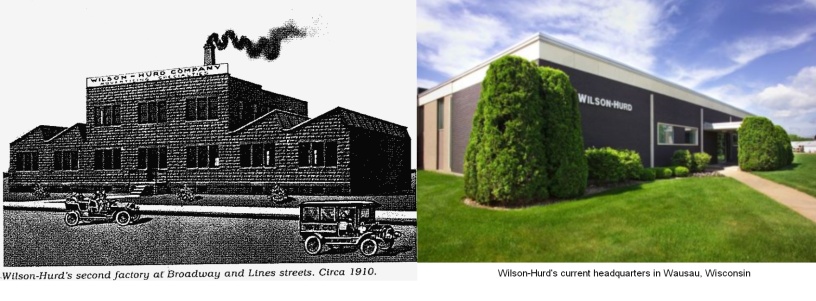

When Wilson-Hurd was established in 1904, nobody had heard of a POP Display, or a Membrane Switch. Surely neither George Wilson nor Arthur Hurd would have imagined that these were the products their company would someday be providing to customers. Although the company, the clientele, the products themselves, and our employees’ fashion sense may have evolved over the years, one factor has always remained the same, and that is quality; the quality of our products, and the quality of our service.

In 1904 Wilson-Hurd was but a small factory located in downtown Wausau, Wisconsin manufacturing a patented bag holder that was designed for agricultural and industrial purposes. Almost 110 years later, Wilson-Hurd has 3 manufacturing facilities in Wisconsin. There is one manufacturing facility still in Wausau, although quite a bit larger than the former, along with 2 facilities in Berlin, Wisconsin. The company went from supplying bag holders, remembrance advertising and nameplates to producing Electronic Control Products, POP Displays, Medical Devices and Custom Metal & Plastic products.

While initially the bag holder was Wilson-Hurd’s specialty, in 1919 the company decided to delve into the Remembrance Advertising market, producing blotter covers, thermometers, whiskbroom holders and hand held fans. 9 years later in 1928, Wilson-Hurd began to print and fabricate aluminum nameplates, which is something that we still specialize in today. Plastic was added to this division in 1979 when Wilson-Hurd began screen-printing and printing on plastic. As technology progressed, other opportunities arose for Wilson-Hurd. In 1993 the company’s Electronic Control Product division was established, kicking off a division of the company that would soon become one of its driving forces. With this new division, Wilson-Hurd began offering customized engineering solutions for data input devices.

Wilson-Hurd’s Electronic Control Product division, or ECP for short, produces a wide variety of the highest quality customized electrical components including membrane switches, elastomeric, metal & plastic keypads, capacitive touch switches and PiezoPanels, along with Engineered solutions that are created specifically to meet the customer’s needs. Today, the ECP division has grown to include electronics for medical devices and machines such as hospital beds, and insulin pumps. Recently, Wilson-Hurd has started a Medical Contract Manufacturing division. This division focuses on developing monitoring, diagnostic, and therapeutic devices. In developing these products, we utilize modern materials and processes including conductive inks and medically approved substrates, to produce disposable hydrogel-based sensors for leading edge medical device owners.

While our ECP and Medical divisions were taking off, we also established our POP Division that creates a variety of POP display components including risers, signage, formed bases, unique logo plates, trim, electronic displays as well as appliqués for cosmetic packaging. Every single component that is created is custom designed to meet our customers’ needs. Over the years many new and exciting processes have become available for our POP Division customers including custom color matching, die-cutting, digital, screen and litho printing, large-format printing, laser cutting and more.

In 2004 Wilson-Hurd celebrated 100 years of service. Although we may no longer make bag holders, we do take pride in the quality of our POP Displays, Nameplates, Electronics and Medical Devices that we are able to create for our customers, many of which have been with us for decades. If we have not yet had the pleasure of doing business with you, we welcome you to take a look around our website, connect with us on Facebook, Twitter, Google+ or LinkedIn, or even sign up for our E-Newsletter, to learn more about us and the things we are capable of. Who knows… maybe you’ll decide to stick with us for the next 100 years!

Wilson-Hurd is headquartered in Wausau, WI with additional facilities in Berlin, WI. For more information on our company and what we can do for you, give us a call at 800-950-5013, or visit our websites; www.wilsonhurd.com; www.wilsonhurdelectronics.com; www.wilsonhurdpop.com

Wilson-Hurd is available on:

Twitter • Facebook • Google+ • LinkedIn

Click Here to sign up for our E-Newsletter